Creating Detailed Textures

with Grown Mycelium

with Grown Mycelium

Jennifer Weiler

in collaboration with Piyum Fernando, Nipuni Siyambalapitiya, and Stacey Kuznetsov

This work was completed as part of a larger project about potential applications of mycelium—the vegetative part of a fungus made up of fine filaments that can be grown on a substrate to take a specific form.

The type of mycelium we used for these experiments are developed and marketed in a 'Grow-it-Yourself' (GIY) kit, wherein each bag contains dehydrated spores mixed with a recycled agricultural waste substrate. As detailed in the vendor's instructions, growing the mycelium kit consists of two stages. First, the mycelium spores are reactivated by adding 3 cups of water and 4 tbsp of all-purpose flour and kept in a cool, dark area for 2-3 days. Then, the contents are mixed with an additional 4 tbsp of flour and shaped into a desired form using a variety of molding and sculpting methods. The shaped material then grows for another 4-5 days and can be cured in a regular oven or air-dried using a regular fan to halt its growth.

To see more about Piyum Fernando's and Nipuni Siyambalapitiya's

experiments growing mycelium, click here.

Physical Replicas of 3D Models Grown out of Mycelium

As part of our mycelium research, we explored the possibilities of growing mycelium forms out of digitally designed 3D models. In this workflow, we started by 3D printing a single copy of a CAD model using a Makerbot 3D printer. We then made negative molds of the 3D printed model using silicone plastique, a commercially available two-part putty solution which, when mixed, permanently takes on a desired shape while remaining bendable for easy removal of mycelium grown inside it. Through this method, we transferred the form and surface details of the 3D printed object to a flexible plastique mold that could be easily reused for growing mycelium multiple times.

To see more about our use of silicone molds in other projects, click here.

Below: mycelium grown in silicone molds (with magnets attached)

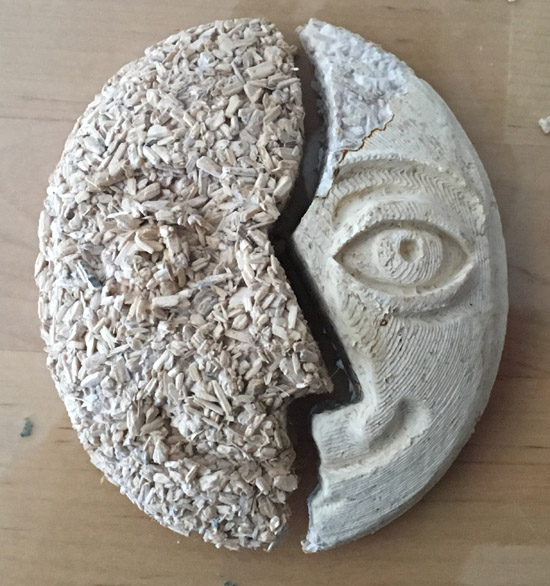

As an experiment to encourage mycelium growth into the small crevices and details of the mold, we tried sprinkling flour onto the mold before adding the mycelium mixture and leaving the mycelium in the molds for 10 days, rather than the recommended 5-6. This approach resulted in mycelium objects that captured nearly all of the fine textural and visual details of our initial CAD model.

In the finished molds, items that were given longer to grow and sprinkled with extra flour appear white (as the mycelium had grown into all the details in the mold) while the mycelium grown under original instructions still have the visible grain of the growing substrate.

In the finished molds, items that were given longer to grow and sprinkled with extra flour appear white (as the mycelium had grown into all the details in the mold) while the mycelium grown under original instructions still have the visible grain of the growing substrate.

Below: finished mycelium objects.

Below: other examples of mycelium experiments. While each result is unique,

items given extra flour and time to grow were able to better fill out the details of the mold.

items given extra flour and time to grow were able to better fill out the details of the mold.